POLYELECTROLYTE PREPARATION AND DOSING STATIONS

OPERATING PRINCIPLE

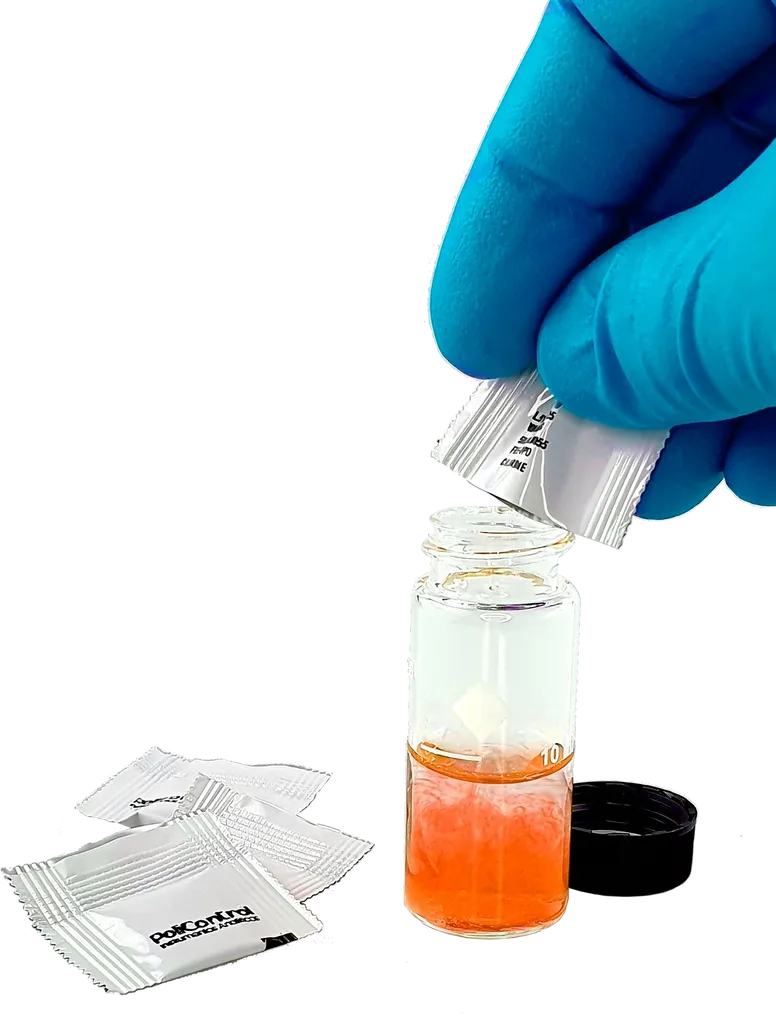

The polyelectrolyte stored in a hopper is conveyed by a screw spiral. Dosing occurs in the first chamber of the dilution tank where the polymers are appropriately diluted with water by an electromechanical agitator to facilitate dissolution.

Once this first phase is completed, the solution is moved to a second chamber to complete the preparation to perfection. The process ends in the third settling chamber.

Similarly, the polyelectrolyte transitions from the concentrated state to the liquid state. A dosing pump is installed in place of the powder dispenser.

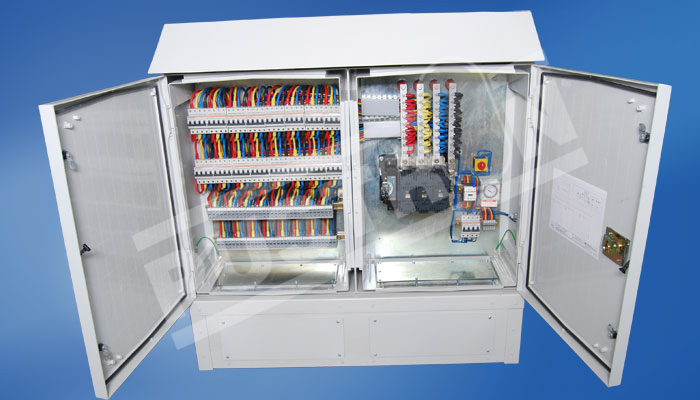

The passage between the various sections is automatically managed and controlled via a system of communicating vessels that automatically stop and resume their function once the desired level for each section is reached.

CONSTRUCTION CHARACTERISTICS

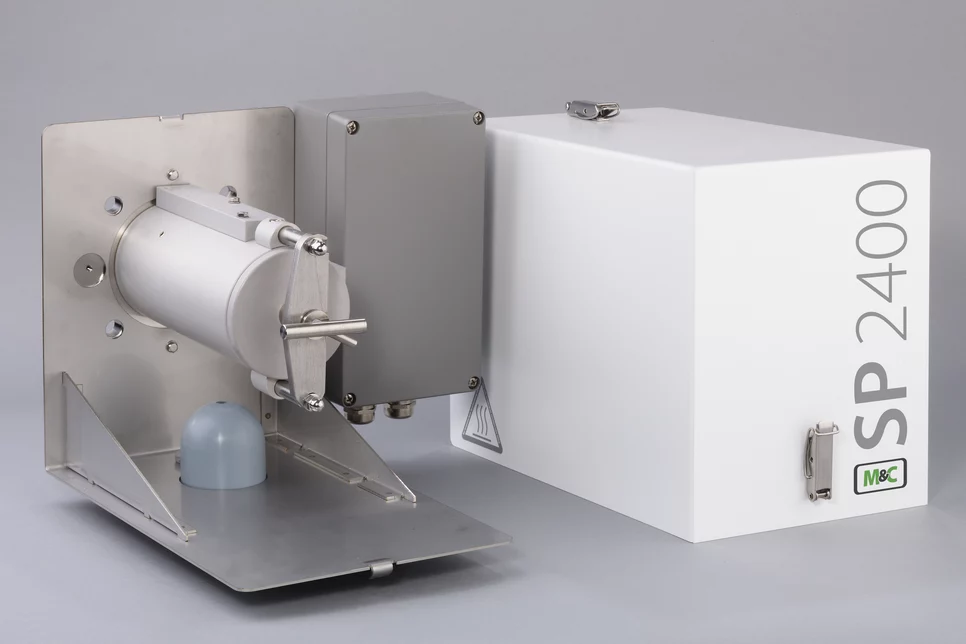

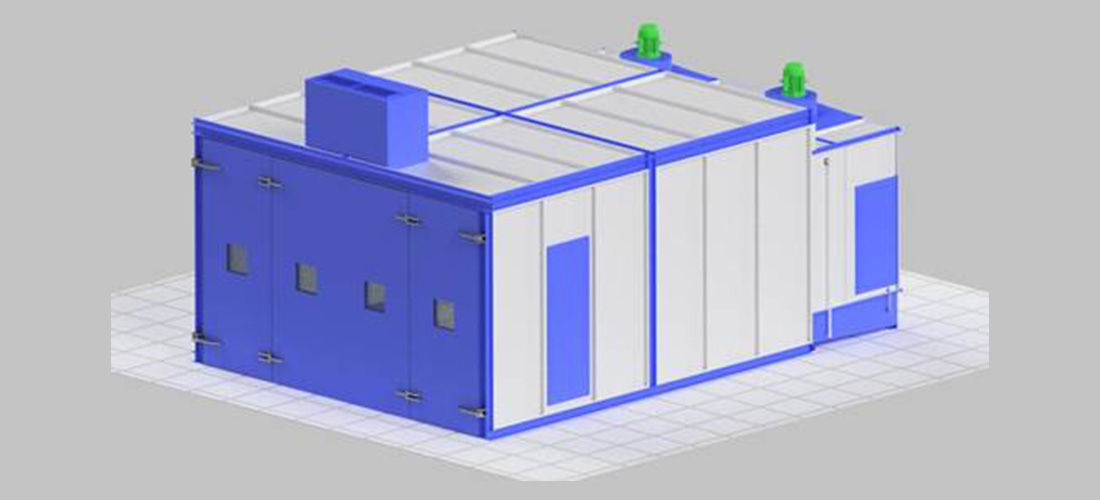

Automatic mixing systems, equipped with two/ three chambers for dosing powdered flocculant to achieve solutions ranging between 0.05 and 0.5%. Such systems include:

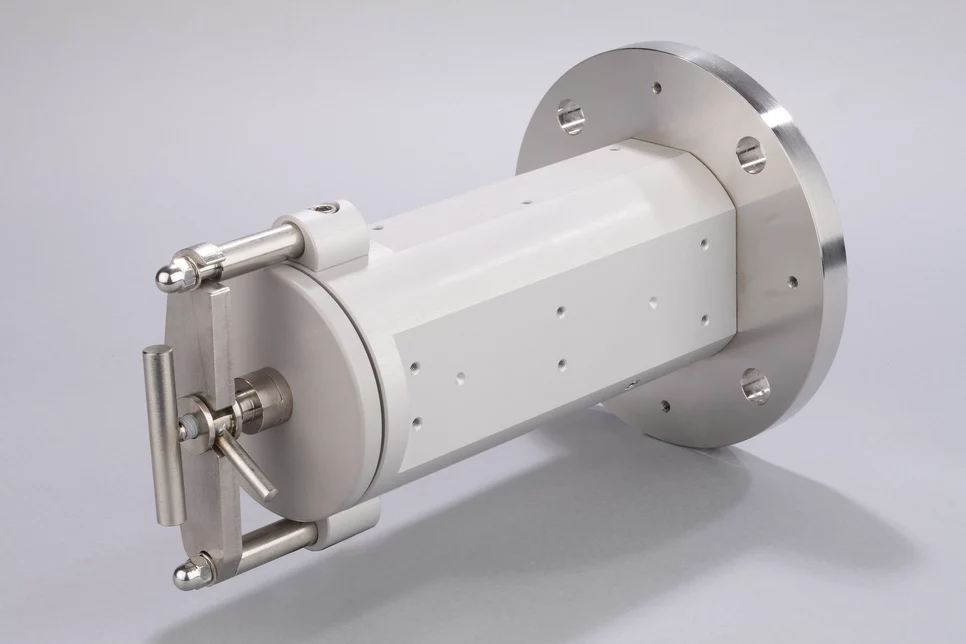

A stainless steel combined container for polyelectrolyte preparation, maturation and storage, with reinforcements and brackets for the other aggregates

Stainless steel bottom outlets and overflow spillways (min 70 lt.)

A dry substance measurement device of variable capacity, a feeding hopper fitted with a hinged cover and seal, and a helical screw blade with a three-phase variable speed motor

2 or 3 motor-driven, low speed electrical agitators made of stainless steel

Pipes for liquid concentrate dosage

A powder washing and wetting system complete with a washing device, nozzles, a flow meter and accessories for treating aqueous solutions.

POLYELECTROLYTE PREPARATION AND DOSING STATIONS

Our polyelectrolyte preparation and dosing stations are specially designed to produce basic solutions or solutions using synthetic flocculants (polyelectrolytes), with the purpose of achieving effective colloidal substance separation. The operator enters the data for the solution concentration percentage, the hydraulic calibration of the powder dispenser and the liquid concentrate dosing pump, according to the current operating requirements.

Our stainless steel preparation and dosing stations are customizable according to the amount of sludge to be treated. They are used during the flocculation phase in depuration plants for conditioning sludge prior to dewatering.

If you are interested in our products, do not hesitate to contact us.