SLUDGE THICKENER/DEHYDRATOR

MACHINE COMPOSITION

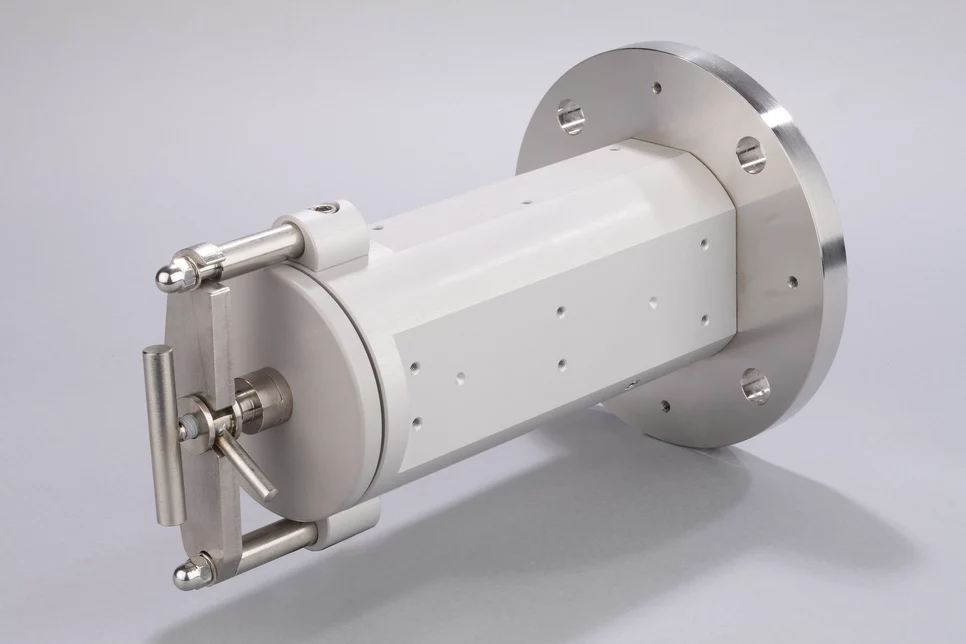

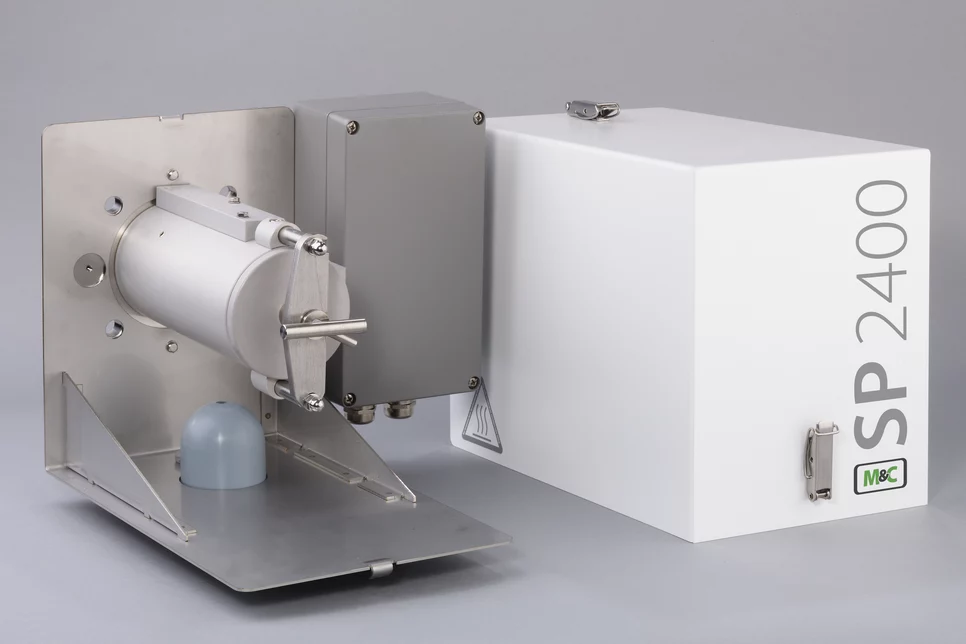

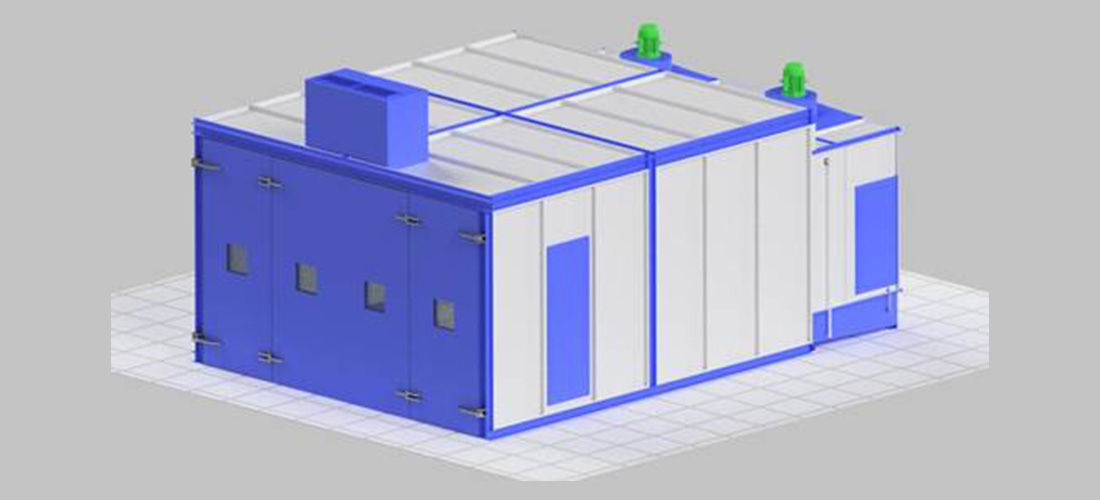

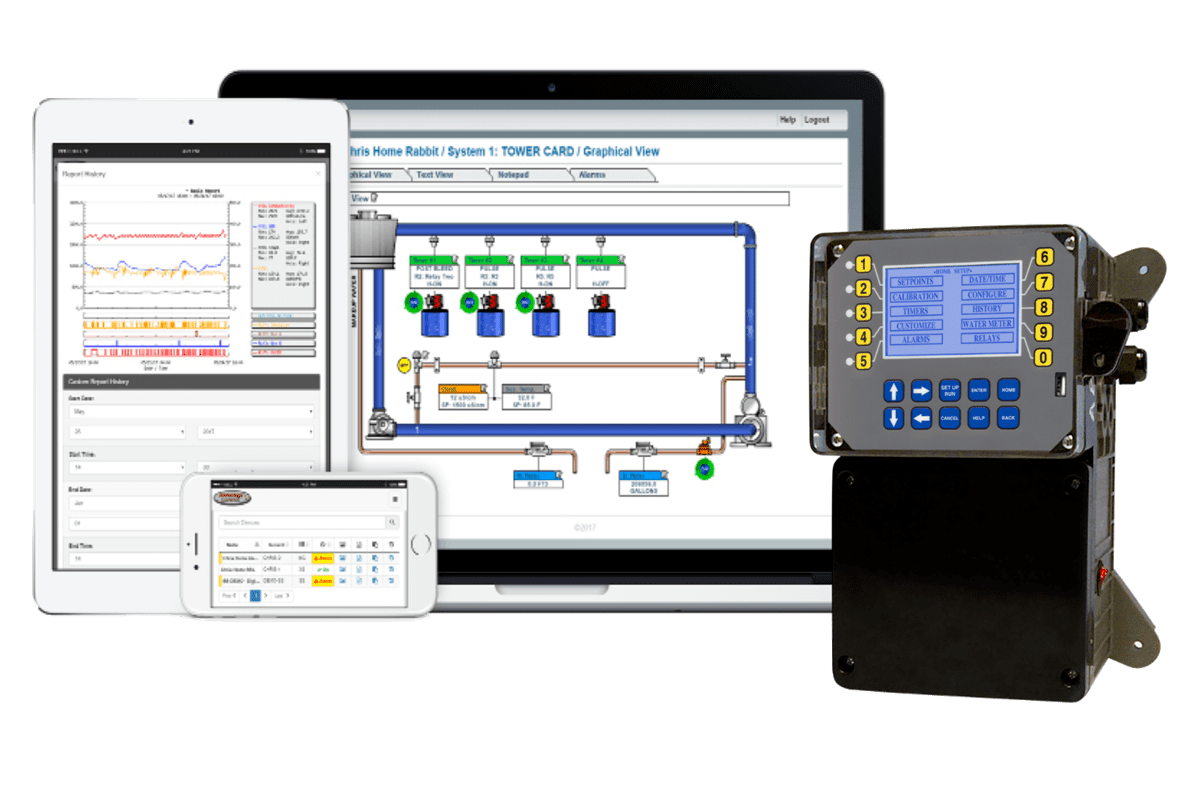

The X-RA version is composed of a flocculation reactor and a dynamic thickener. Compared to the previous versions, this machine features a module for mechanical sludge dewatering, which can be installed at a later stage to avoid plant stoppage. In fact, if the X-RAD version is installed in combination with sludge dewatering device and the latter needs to undergo maintenance, a third module takes the place of the one undergoing maintenance.

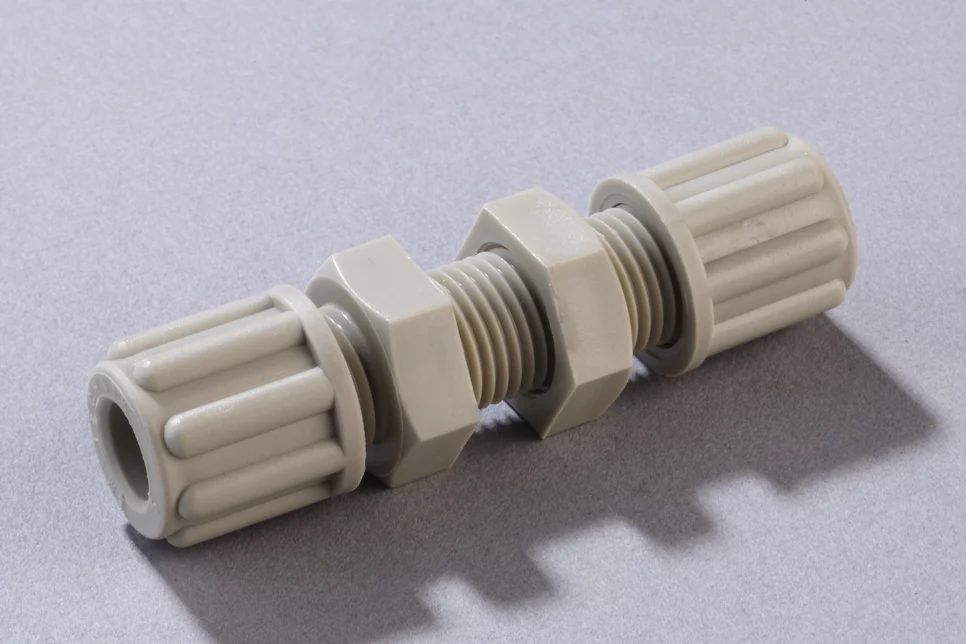

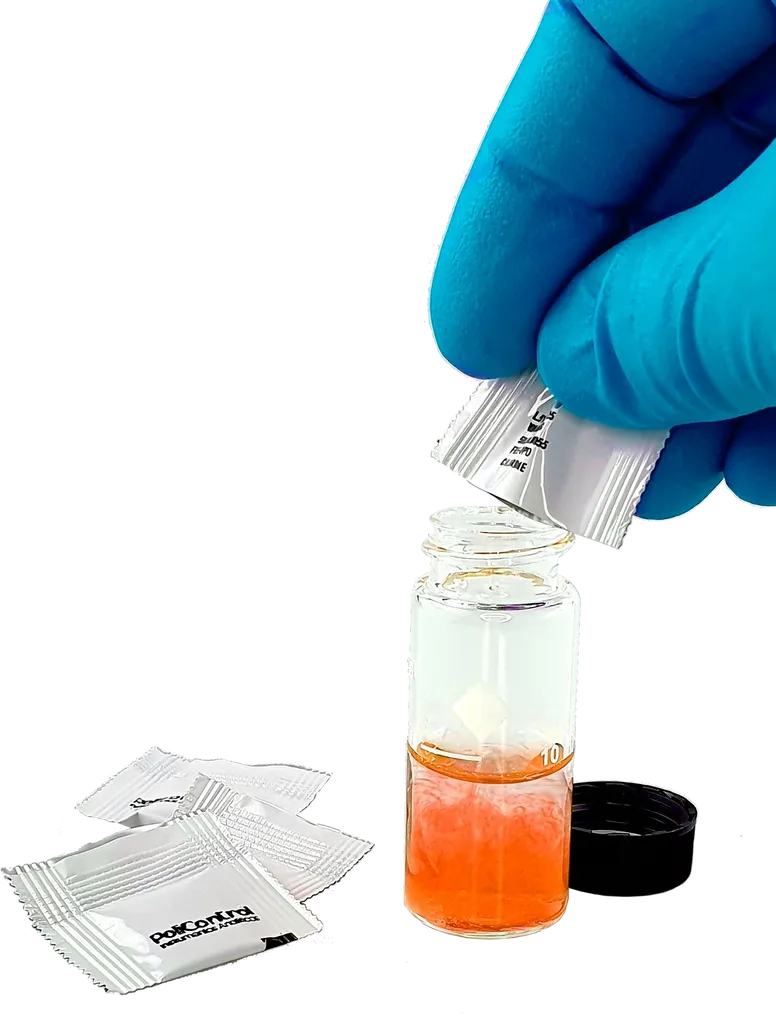

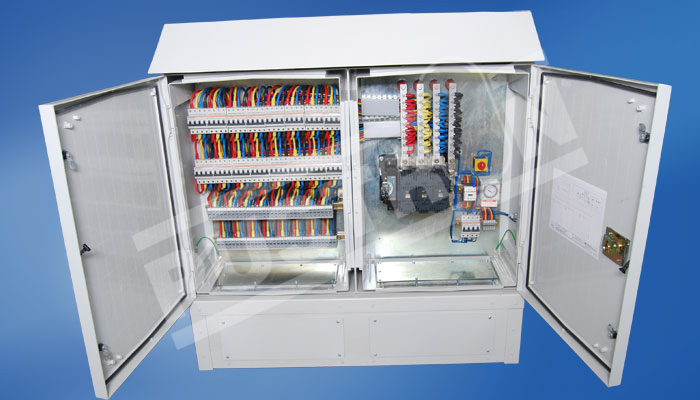

The machine is mainly made of AISI 304 and AISI 316 stainless steel. An additional polyelectrolyte preparation and dosing system and an electrical control panel can be supplied upon request.

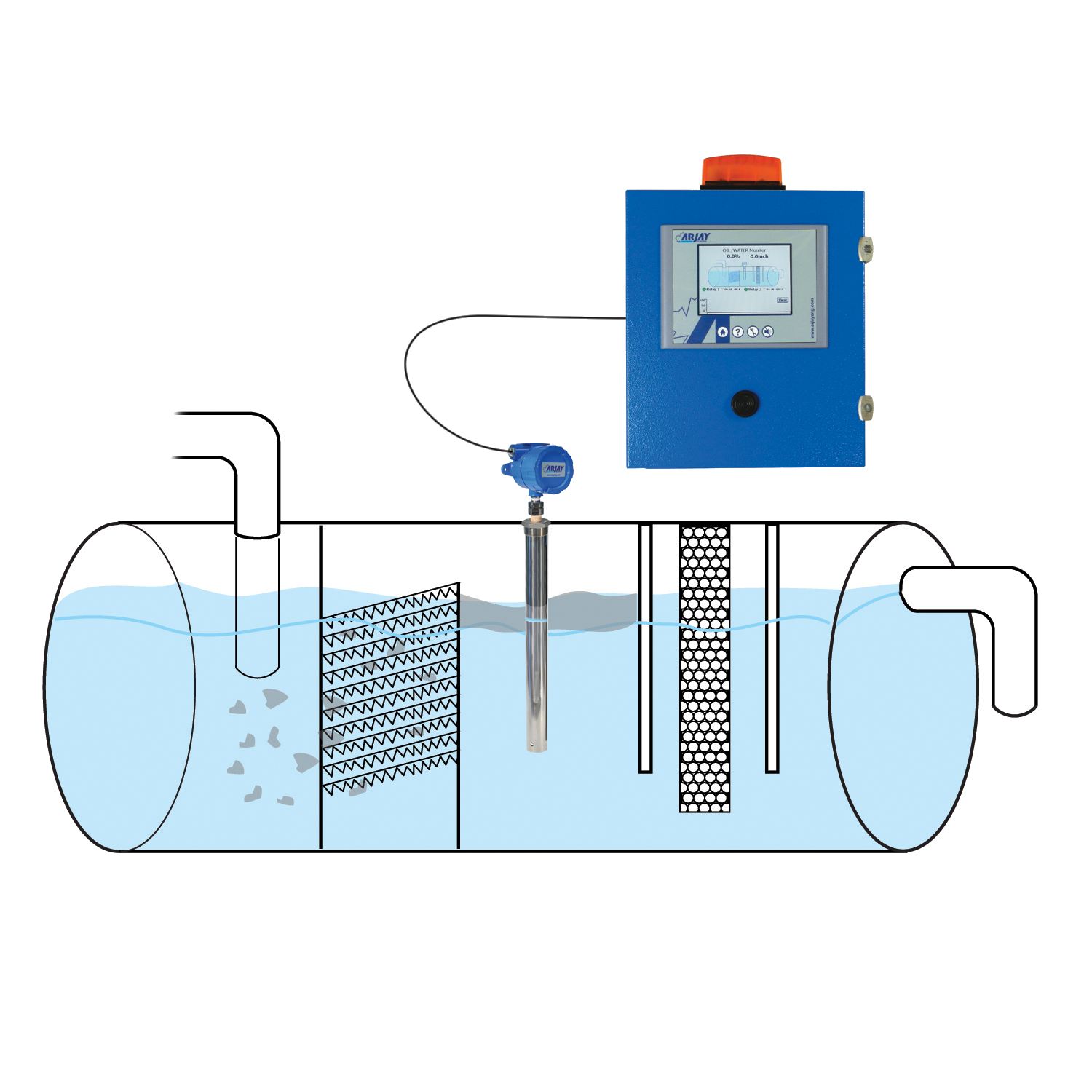

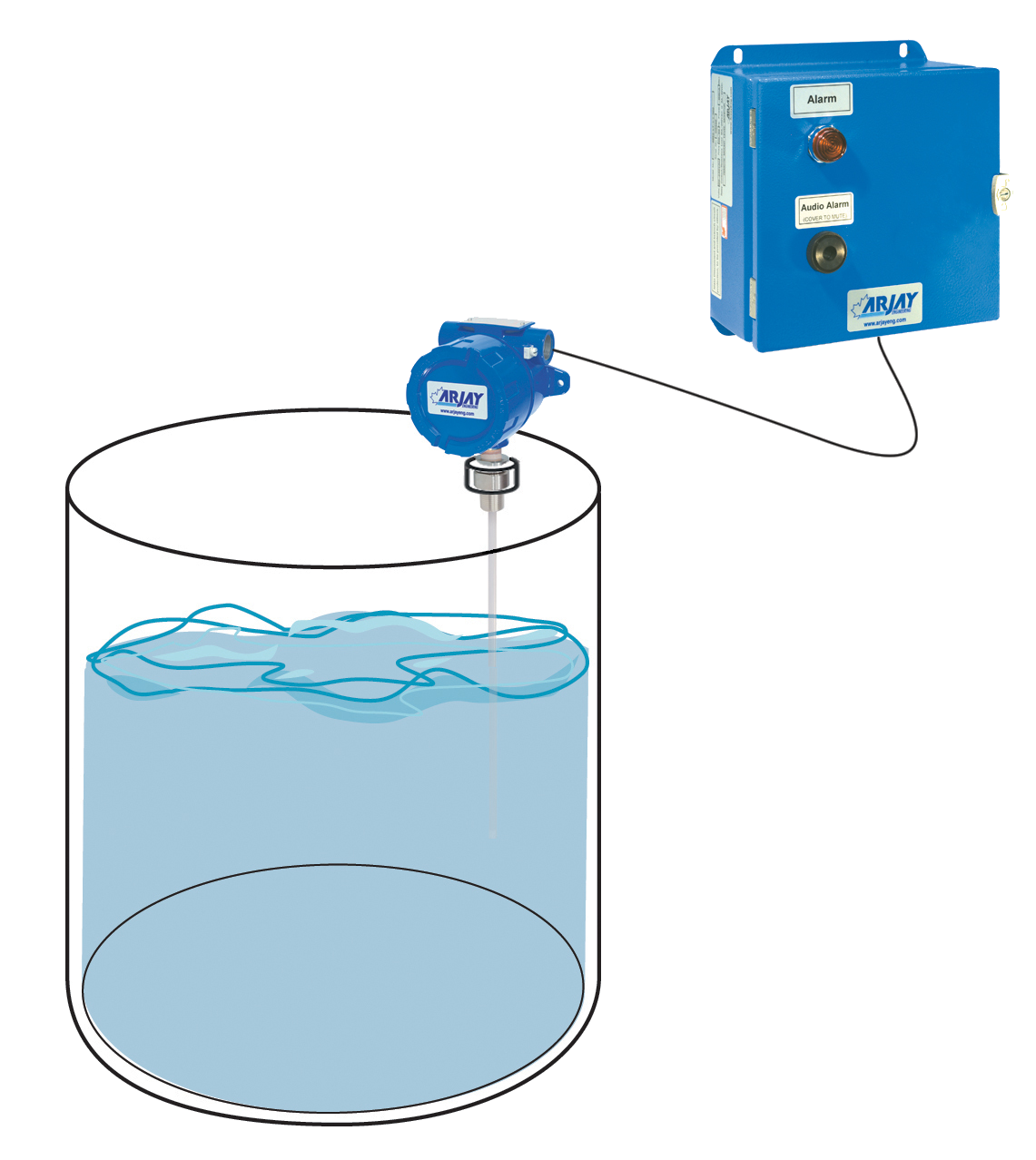

The thickeners/dehydrators we make are used in a variety of sectors: energy and electric power sector, mining/metallurgy, water treatment, and recycling. In general, they are perfect systems that can be applied to production plants that use large amounts of water, with the aim of purifying it and putting it back into circulation free of sludge, pollutants and other wastes.

The X-RA and X-RAD models are specially developed to reduce and amortize investment, operating, and maintenance costs.

We can develop customized solutions at the customer’s request to adapt the machines to any system, either existing or yet to be constructed.

Contact us to inquire about the supply of our products.

Enquire NowSLUDGE THICKENER/DEHYDRATOR

Our new product range provides a solution to the increasingly topical issue of thickening and dewatering sludge coming from settling tanks installed in depuration plants. Our thickeners /dehydrators come in two different versions: X-RA and X-RAD, both of the modular type.

If you are interested in a modular, dynamic sludge thickener, contact us for a free quote. We produce high- quality, reliable equipment.